1994 Chevy 6.5 Diesel Firing Order – If you’ve actually utilized an Chevy 5.3 and were actually puzzled by the firing pattern it’s not an issue. This post will street address one of the most regularly requested queries, and explain to you where every single tube should really be firing. It is possible that you are contemplating whether you should alter the order. Alternatively, if you are able to use the factory setting. Either in scenario, learning the specific firing buy for your 5.3 could save you from frustration. Learn the appropriate method to use to make use of with the engine. 1994 Chevy 6.5 Diesel Firing Order.

5.7L engine’s firing order for firing is 1-8-7-2-6-5-4-3

This Chevy 5.7L engine’s fireplace sequence begins with variety eight, which is the driver’s aspect, then techniques towards the complete opposite finish with the cylinders with even amounts. This is because, once the cylinders are put into these combustion chambers they will rotate in a single cylinder pattern. It is different from the firing pattern of the Chevrolet LSX engine, although the firing sequence is similar to the firing order on the 5.3L engine.

This is the Chevrolet 5.7L engine’s fire sequence is just like the LS1 counterpart. The ZR-1 was discontinued within 6 years of its generation. In 1997 the LT5 was introduced as an alternative to Corvette managers. Chevy Corvette, as well as the company was quick to produce it in large figures. The 5.7L was developed with an light weight aluminum head and block to boost strength and endurance. The 5.7L’s ability when compared with it’s Gen I predecessor was considerably better.

When switching heads The LS7 cylinder heads may be used with many other LS engines. The absorption dock diameters in the LS7 are different from those of that relating to LS3 along with LS9 heads. The LS9 head isn’t capable of being added to an prevent that may be LS1 or LS2. The LS7 go is specific from LS1 along with LS2 disables. The LS7 prohibit consists of 12mm mounting bolts to attach the pinnacle of the tube.

The LS number of engines was constructed utilizing the light weight aluminum prevent although previous metal blocks had been made of iron. The newest number of heads for cylinders had the 15-diploma direction control device direction as well as improved combustion compartments. Alongside an advanced ignition mechanism, the firing design that is used with the Chevy 5.7L engine is 1-8-7-2-6-5-4-3. The exhaust manifolds were also upgraded.

If you’re installing an engine with LS1 or a Gen III engine, you have to update the table to reflect the latest ignition system. Before the engine can be put in place, it is crucial to ensure that the various ignition devices are in sync. For your LS1 and also LS3 motor is going to demand connection from the induction PCM and banks. The transaction of firing of Gen III engine is Gen III motor is 1-8-7-2-6-5-4-3.

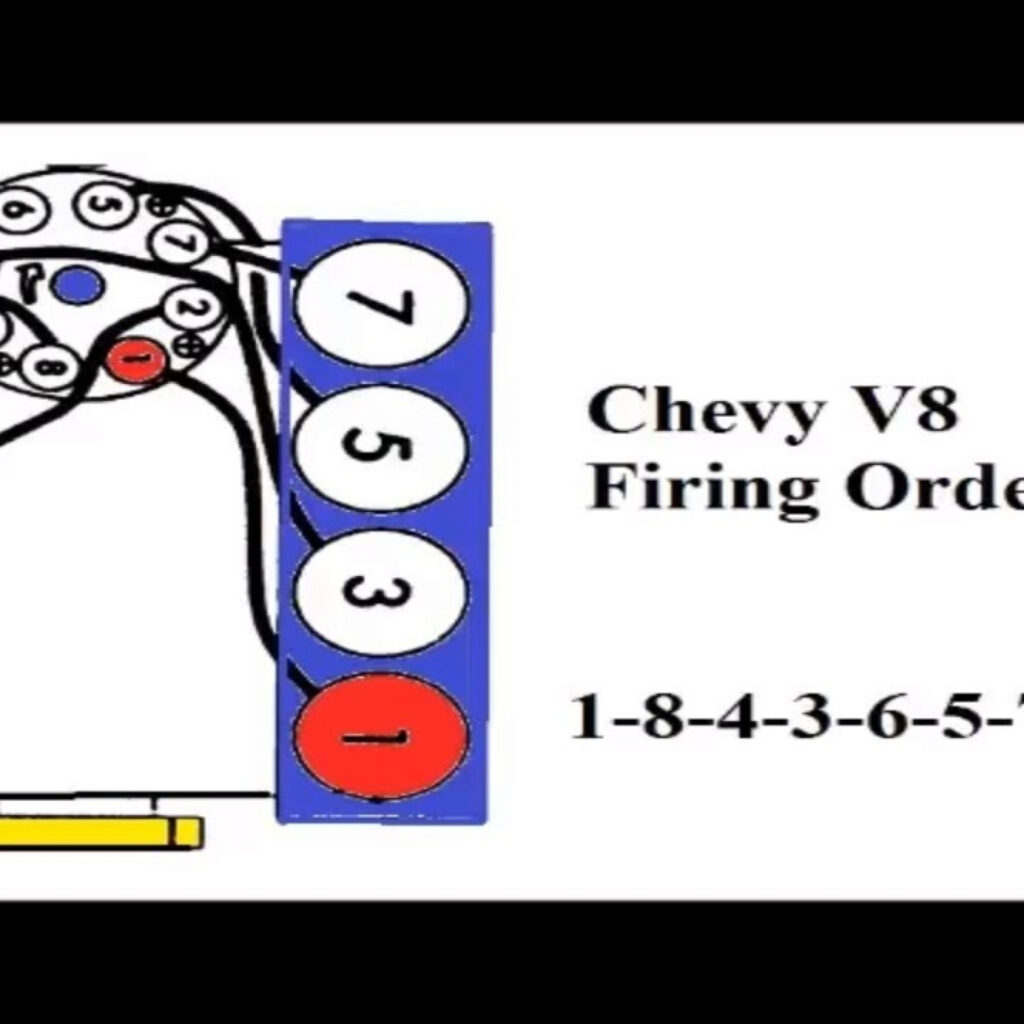

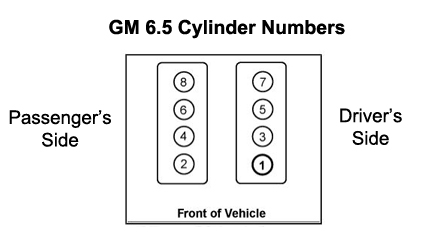

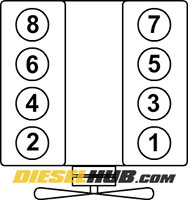

5.3L engine’s firing sequence is 1-8-4-3-6-5-7-2

You’ll need to understand the snapping shots pattern for the GM 5.3L generator to obtain optimum functionality as a result. It’s distinct from other Chevy lorriesthat have SBC motors. The firing pattern to the 5.3L Chevy motor is generally 1-8-4-3-6-5-7-2. It is different from other engines that make use of SB and also BB V8s.

The 1st cylinder from the 5.3L is found to the left in the generator. In cases where the tube is situated located in the center of the generator then change 90° to make the crankshaft remaining. This leads to that engine to rev faster. The following cylinder in the firing order can be found in midsection. This produces a lot more pressure. The final cylinder is located on the top rated inside the engine.

The firing purchase of your 5.3L motor is the same for your 350. It is regarded as to be a V8 with slightly more power, though a Z/28 engine has the same basic structure of a 350. Both engines have ingestion plug-ins that happen to be swirled and ingestion ports that GM phone calls “vortex compartments”. This could reduce airflow and power output. It’s also employed to save lots of gasoline.

It is the 5.3L engine’s firing routine can be described as: 1 piston is turned off at TDC whilst the next one is stimulated. This happens following the strain in the ingestion manifold rises. Because this comes about the gasoline injector is just not lively until the cylinder has achieved TDC. The gasoline from the cylinder that is not stimulated is pulled into the cylinder and then ignited then burned up for restoring regular engine procedure.

It is the 5.3L engine’s firing design is among the most complex aspects of the LS-combination of motors. The gasoline injectors are switched in ways that the PCM has to be aware of which injectors are operating and which aren’t. Incorrectly-mapped injectors can bring about excessive gasoline trims and also stalling. Andin specific cases the engine could quit entirely.